My first blogging injury.

pencil talk reader Joshua kindly sent me some Mega Brands SRX pencils. Mega Brands has been mentioned here before as the owner of the RoseArt brand, which is a longtime U.S. pencil manufacturer.

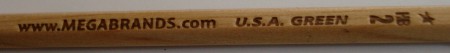

They now have some pencils in the Mega Brands name, with RoseArt unmentioned. One of these is the “USA Green”, presumably an extension of their “USA Gold”.

The pencil package states:

USA Green is an earth friendly cedar wood pencil with a high quality graphite core.

The package also notes that the pencil has neither lacquer nor foil stamping. It is made in the U.S.

I was using one, testing it out, when I noticed something extremely unusual – the pencil appeared to be made from four pieces of wood – not the traditional two. Other pencils were made from six pieces of wood.

Coincidentally, I came across a similar pencil a day later at a local bookstore. Made in Japan, this was a very nice looking triangular pencil sold by “Green Apple school supply”.

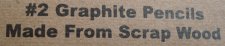

It similarly was made of multiple pieces of wood – and this was acknowledged on the package. Here is what they say:

Green Apple #2 graphite pencils are made using scrap wood and finger joint construction.

There is the descriptive phrase we need – “finger joint construction”.

To get a better view of what was going on, I tried to split one apart – and got a rough splinter in my finger – my first blogging injury. Luckily not my writing hand. I didn’t learn too much from this interrogation.

Maybe someone with some wood working knowledge could share some information about what’s going on. I’m not sure if this constitutes a new pencil production technique, but it is certainly very interesting.

It appears that the pencils are made (as usual) from pencil slats, but that the slats have been constructed via this finger joint process.

In any case, if this technique is part of a new strategy to compete with the rolled newspaper pencils, I can see it having some appeal.

We’ll look at some other Mega Brands SRX pencils in the days ahead.

As pencils, both have merits. The Green Apple does have a very nice triangular shape and finish, while the USA Green gets a nod for a quite smooth rich lead, especially for what would appear to be a discount pencil at first glance.

Well I can’t comment on these pencils specifically, but as I understand things, fingerjointing ‘shorts’ together to make a longer length is standard practice in the woodworking industry. Here in NZ all skirtings, decorative mouldings, etc are all fingerjointed. Buy a 3m (10ft) length of skirting or frame and it would commonly be 5 to 20 pieces jointed together. Done correctly, the joint should be good and strong. Now I think about it, I’m almost surprised a certain percentage of pencil slats aren’t always routinely finger jointed. I mean trees don’t conveniently grow in pencil-length multiples so there must always be a part slat left over. Why waste it?

We’ll wait for the real authoratative answer from Woodchuck?

What good timing as I just ordered some of the Green Apples (I like anything triangular).

kiwi-d, thanks for the comment. Indeed, who knows what’s lurking beneath the varnish of most pencils? Finger jointing could be quite common.

Diane, I think you’ll like them. Do you know Levenger? They’re also selling a natural triangular pencil.

I received the Green Apples, and some other things, today — I do like them. The lead is smooth, not smudgy, and wears well. Probably isn’t as dark as some would like, but it worked for me.

I do know Levenger, although they’re pricey for me. I looked for pencils, and they seem to carry mostly expensive mechanicals. It’s okay because I really don’t have any room left to keep feeding my habit. :)

While in Japan recently I got a box of reclaimed wood pencils made by Tombow, I think. Haven’t gotten around to using one yet, but it’s nice to see this is an emerging trend. I can’t think of any reason why they should be inferior to regular woodcase pencils, except for maybe an increased risk of splintering when sharpening the fingerjoint area.

I look forward to your future findings with these and other reclaimed wood pencils. I won’t be getting around to mine for several weeks (got a schedule for all the new loot I picked up in Japan!).

Stephen, I like that post very much. I think that recycle products are great. I especially like the joint detail! And to be sure it is made of wood. Often my pencil feels like it’s been coated with that yellow layer of plastic.

-Duc

Thanks for the post Stephen. I just submitted my order for a few dozen of the Green Apple pencils. They hit on two of my favorite attributes: a natural finish and triangular shape. The construction of these sounds interesting too. Here’s where I place my order: http://tinyurl.com/6ao572

Stephen,

It’s been some time since I reviewed your blog so found several posts of interest to comment on.

Your readers are correct about longer time use of fingerjoint slats.

Our company California Cedar Products COmpany originally developed the first fingerjointed pencil slats back in the 1970s so the use of these has been around a long time in th pencil industry. Basically it’s a way to recover more finished slats from shorter peices that would otherwise be ground up by the slat factory and sold as waste fiber for other uses,traditionally in our company Duraflame firelogs. Technically the edjeglue joint is stronger than the wood itself if done properly and when you break a pencil or slat on purpose the break will not occur at the location of the fingerjoint. There are also edge-glued slats in which two narrow slats are glued together to make a wider slat.

Until the past 5-10 years probably 95% of fingerjoint slats went to the Japanese market, primarily because the government has for some time required “recycled” material in their voting pencils for elections. The fingerjoint qualified as recycled as it used a part of a slat that would otherwise be not used in a pencil. The Japanese also did some interesting creative pencils featuring the fingerjoint of different colored woods together, I have a beautiful set of examples.

Our company produces only a very small proportion of these slats given that most of our short slats get sold for use in short cosmetic pencils. However, some other manufacturer’s have introdued fingerjoint as they have not been able to develop a short slat market and have a higher proportion of fingerjoint and edgeglue slats in theor overall production.

With more interest in “green” earth friendly products and pencil manufacturers trying to save cost the fingerjoint slats have been begun to be used in other products, sometime positioned as green sometimes simply as a wood cost savings in existing brands that you do not notice becasue they are painted over.

Thanks WoodChuck, your comments are always welcome here!

ESTIMATED FRIENDS:

WE ARE A COMPANY DEDICATED TO THE SUPPLY OF DIFFERENT PRODUCTS IN VENEZUELA. THEY WE ARE CONTACTING IN ORDER THAT THEY GIVE US 20.000.000 IT(HE,SHE) GIVES PENCILS OF WOOD IN RED COLOR THAT THEY HAVE THE FOLLOWING TEXT WRITTEN: ” REPUBLICA BOLIVARIANA DE VENEZUELA ” WE NEED OF URGENCY TO KNOW THE PRICES OF THE PENCILS AND THE AS IMMEDIATE AS POSSIBLE TIME OF DELIVERY. BEING GRATEFUL FOR HIS(ITS) ATTENTION TO THEM, I STAY OF YOU

ATTEMPT ME

JOSE LOZANO C.

GENERAL MANAGER

LAIMACO, C.A.

Av. URDANETA c/c SUCRE

MONTALBAN 2042, ESTADO CARABOBO

REPUBLICA BOLIVARIANA DE VENEZUELA

TELEF: 00+58-416-7388821

Twenty million pencils! I hope someone in the pencil industry is reading.

“Diane, I think you’ll like them. Do you know Levenger? They’re also selling a natural triangular pencil.”

I’m back to say I just got a tube of these as a little gift from a friend who saw them at a Levenger’s counter at Macy’s. They look good!

I just got a pack of the usa green pencils and I love them.I love how smooth they write. They sharpen easily in any sharpener and don’t splinter.

we are opening a new pencil factory.we import most of machinery. but for pencil slat , we are trying to make machine byourself.

but more than 6 month still we can not successful in it.

kindly advise me from where i can buy pencil slat making machine. we will use popular wood .

kindly advise me about it.

Hi Kashif,

What part of the world are you in? It’s quite ambitious to be opening a new pencil factory at this time.

If you look at an industry directory, you’ll see that most of the listed “pencil” companies deal with the manufacturing infrastructure. I’d start looking there.

thanks PENCIL ADMIN,

I AM IN PAKISTAN ,I BOUGHT MOST OF MACHINE FROM CHINA.

AS FOR THE WOOD SLAT CHINESE MACHINE ALSO NOT WORK HERE .

SO I NEED YOUR HELP TO GUIDE US ABOUT IT. KINDLY ADVISE ANY FACTORY WHO IS MAKING WOOD PENCIL SLAT MAKING MACHINES.

OUR ALL OTHER SETUP IS READY.WE HAVE INSTAL ALL MACHINES.

Pencil made out of “Finger Joint” wood can not be called Pencil made with SCRAP wood!!

We all know that every day thousands of trees are cut to procure wood for making various timber products. Pencil is one of the most common and CHEAPEST Product which consume wood in HUGE quantity. Beside this the wood which is used for making those pencils are very expensive and therefore every Pencil Maker intent to use every small piece of wood converted in to a Pencil!!

When you compare the price of a Pencil with the “Finger Joining” proccess, this proccess is more expensive thaat price of a Pencil. But the Pencil Manufacturer gets satishfaction by adoptig “Finger Joining” proccess that he or she has given justice to every inch of a TREE to make Pencil and have save some precious wood and helped the mankind to “Preserve Planet Earth” by preserving tree and enviornment!!

We are practicing this proccess from last 20 years for making Pencils and Pencil Slats.

Dear Mr. K. Asif,

I do agree that Pencil Slat Cutting Machine from China is ver difficult to put in production…

But if You put your best efforts, you can use this Machine!!

I am sure you must have purchsed “Pencil Board(SLAT) Cutting Machine” which use a KNIFE to slice the “boiled & coocked” wood like making “potato chips”…

If you feel that you can not use this machine, than you should buy

“Multiple Blade RipSaw” machine or “Multiple Blade FraeSaw” machine.

Those machines also can cut Pencil Slat with a very precision workmanship. Such machines are available in Taiwan / Korea / China / Germany / Italy.

The ‘BEST’ Machine is manufactured by “Weinig” of Germany.

As you belongs to Pakistan, if you can come to India at DELHI in Mid Febrary 2008, I can put you across few machine manufacturers. As we are having India wood 2009..

Harshad

Dear Friend,

When we compare the price of Cal Cedar Slats for converting them in to Pencil, the price is too high and we are never offered better price of Cedar wood Pencil.

The moment we try to export those pencils, our overseas buyers offer us throw-away buying rate…

Why it is like thi??

Are those slats sold to us at higher price than the others??

My Company manufacture nearly 3 million pencils everyday and we consume huge quantity of Pencil Slats (nearly 0.7 million every day)

Can you suggest me the reason???

Harshad

Hello Harshad,

Thank you for your thoughts and insights.

We are definitely happy to have comments from members of the pencil industry!

This is a non-commercial website, for the record. We discuss pencils, but have nothing for sale.

I hope you are aware that most of the pencils discussed on the site are not typical – we try to focus on the highest levels of quality.

When you try to export pencils – these aren’t the ones you are competing against – I think your competitors are very cheap pencils from China.

I can’t comment on slat pricing, and can’t claim to know about that aspect of the industry. What species of wood do you use? How do you compare it to cedar?

But maybe you can answer a question – what are the relative costs of the wood, lead, and paint in a pencil?

Thank you.

Dear Penciladmin,

Thanks for your responce…

It is great opportunity for me to discuss ‘Pencil’ at this discussion forum..

According to our manufacturing process and costing, our ratio of Pencil is as under:

(1) 33% is cost of Treated & seasoned POPLAR wood Slats.

(2) 12% is cost of lead (10.5 + 1.5) Lead and adhesive (Extra Dark)

(3) 25% is cost of Paint

(4) 22% is cost of Ferrule & Eraser

(5) 08% is cost of Packing

These are Raw Material and Packing Material statestics.

We calculate 40% of all material value as Labor/overhead and add 10% as profit….

Those wood used in India for making Pencil are:

Indian Cedar (Deodar) for Expensive pencils

Inscene Cedar For Expensive pencils

Poplar (Indian) For Best quality Pencil in Indian & Export Market.

Vatta (Indian) For Good quality Pencil in Indian Market.

Elav/Semul For Good quality Pencil in Indian Market.

Cotton Wood For Cheaper quality pencil. (we do not use this wood)

I am in this industry since 1973 and have seen so many rise & fall in Indian Pencil Industry. The manufacturer who was the leader in 1960 is no more in this business and who entered in this business during this year is the LEADER of this Industry.

According to me, the per day production of Pencils in India is somewhere around 8.5 million pencils.

The share by leader is 65%, our company share is 25% and rest 10% is share of unorganized manufacturers.

Our hometown, where our factories and leader’s factories are located, produce nearly 65% pencils of India. Both of us have plants in other state where 25% pencils are produced.

I am fond of writing and have written lots of articles on Pencil.

If you wish and support, I can share those with you time to time, even if someone belonging to this industry needs some assistance, can extend my support.

Thanks..

Harshad Raveshia

raveshias@hotmail.com

Hello Harshad,

Thank you for your detailed and knowledgeable response.

I am sure that many of us are fascinated by your remarks, and appreciate getting this insider’s glimpse of pencil production.

I do hope we may have the opportunity to learn more from you in the future.

Some of this information, such as the details of manufacturing costs, and the range of species used, constitute great information for those of us interested in the pencil business.

Dear Reader Friends,

Can someone enlighten me the all kinds of test done on Pencil??

What are the parameter of all such test on Pencil and Pencil Lead??

Please suggest

Harshad

we are prdoucing wood pencil.we are new in this field. Actuallly we are using papular. But its bit hard during shrpen the pencil.

Is there any chemical or any process which can make it soft..

HI FRIENDS,

I HAD READ ALL THE COMMENTS ON THIS SITE THEY WERE REALLY GREAT BUT I HAD VISITED A PENCIL PLANT BUT DID NOT UNDERSTAND A PROCESS OF TREATING SLATS

I WANT TO KNOW THE BEST SOFTENING TREATMENT FOR PENCIL SLAT.

PLEASE SUGGEST

RAJNISH

e-mail pintoochawke@yahoo.com

Thanks for the lead to this thread, Pencil Admin. Hopefully you can score some of those new Papermate Classics natural wood pencils with the same construction. Looks like Sanford has gone into this “finger joint” technique in a major way now (even for the Black Warriors). I tend to sharpen pencils until the point where the ferrule rests against my hand, so these joints eventually show up.

I had missed this thread the first time around I guess.

WE are interested in your Green Apple Pencils. This is for one of our Clients..for a quantity 10,000 pieces with a Branded Name on the pencils.Will be pleased to know your response.

Best Regards, Suranga Lukmal

Can someone tell me were to purchase a pencil slat cutting machine in the united states.

Where do you buy the green Apple pencils, I can’t seem to find any?

Tabitha, thanks for the comment. The Green Apple pencils were purchased at retail in 2008. Even then, they were of unstated (other than “Made in Japan”) origin. They are likely not in production in 2021, but there are many other finger-joint pencils that can be found, if that is the feature you’re seeking.