One of the great advantages of leadholders is the wealth of available methods for pointing the lead. Let’s take a look!

Sandpaper

This low tech approach is still in use, and an appropriate grade sandpaper is generally for sale at art supply stores. Some pencil / art supply firms have their own branded sandpaper, sold with ten or so sheets stapled to a wooden paddle.

How does it work? If you haven’t tried it, you might be in for a very pleasant surprise – it is remarkably easy to create an excellent conical point, or should you prefer – a chisel point!

The only downside is that you have to be careful about the stray graphite powder getting on your artwork, clothing, etc.

Sharpeners

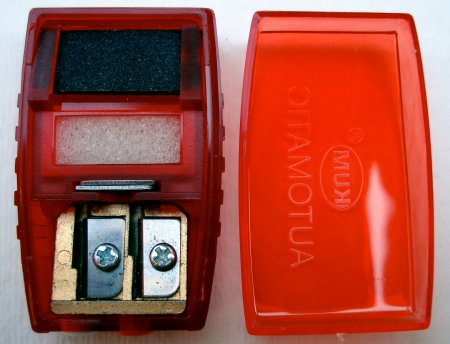

The general-purpose handheld pencil sharpener has been adapted to sharpen 2.0mm, 3.15mm, and 5.6mm leads. Almost every sharpener in this category that I’ve seen (with one amazing exception that we’ll look at in a future post) is made by KUM. Now there are other brands and labels – but every single one I’ve seen, whether from the US, Europe, or elsewhere, appears to be a rebranded KUM product. I guess you could say they own the category!

These sharpeners work extremely well, and I think the blades, touching just graphite, will last much longer than their woodcase pencil sharpening cousins. If part of a container system, they also have the advantage of containing the resultant graphite dust.

KUM makes a version (the 23A R) that includes 2.0mm and 3.15mm brass housed sharpeners with two spare blades, plus a sandpaper area (extra sheets included) and a sponge for post-sharpening cleaning. Very nice.

A more basic version, the Onit 250, has a container for the graphite dust. I have rebranded versions of the 250 from Faber-Castell, Staedtler, and Koh-I-Noor.

They also have a very basic sharpener, the 233, that is possibly the smallest and least expensive pencil accessory around, while still being quite useful.

A larger model, with a metal sharpener and round canister, resold by many, can handle 5.6mm leads.

Cap sharpeners

Some leadholders have a small sharpener in the cap. Usually underneath the cap, the sharpener can also be facing outwards, as with the Criterium.

Montblanc’s cap sharpener is a work of art by itself.

Most such sharpeners have a blade pair forming a crosshair inside the cap.

As to sharpening, the quality of the implementation varies. Some are perfectly usable, while others are more in the ’emergency use’ category.

Since there is nowhere for the graphite dust to go, they can be the worst at creating an unexpected mess.

Specialty pointers

For serious users, there are also specialty pointers. The lead is pointed by rotating it around either the interior or exterior edge of a sharpening blade or ring.

The Staedtler 502 tub is a classic. Did anyone ever get it to work on their very first try? The instructions are on page 13 here (PDF format). It does work! Basically, stick the leadholder in the opening, and turn clockwise. It will seem simple after a few tries.

Rotring also has a version. Basically similar to the Staedtler, this made in Germany pointer has a wider circumference blade, and some fashion forward styling, with an orange body and interchangeable conical guides in four colours. They also kindly provide a couple of spare sponges.

Gedess is a bit different. It has a sandpaper-like rough metal surface, and the lead is rotated around the interior of this blade. The system is remarkable simple.

Some more information from leadholder.com:

There were some very serious desktop models once made, but in the era of CAD, they are long gone.

Other Considerations

Clutch leadholders in a traditional drafting housing work with all of these sharpening methods – but leadholders with newer push-button mechanisms – which are essentially mechanical pencils with wide width leads – don’t necessarily have the grip strength needed to use a sharpener – the lead, not being tightly held, just twists.

And wider bodied systems, even if having a clutch mechanism, may not be able to fit into the specialty sharpeners.

Further reading: the excellent leadholder.com.

Yaay! I’m not the only one collecting lead sharpeners. Nice photos and great collection of leadpointers. Specially like the Gedess shot showing its internal cone, for I have considered getting it in the past. Though that would be rather excessive since a couple of the KUM sharpeners already meet my needs. The blades on my KUM 23A R remained sharp and functional for a good year before I had to use the spare blades.

Thanks Alberto, I’ve observed that you enjoy leadholders!

(I would like to leave comments on your blog, but it wants me to sign up for Blogger, if I understand correctly.)

Just tweaked my Blogger comments settings. It should allow comments from anyone now. Thanks for letting me know about that limitation.

Alberto, thanks for tweaking your comments setting. I think there are others like myself who have wanted to leave comments on your excellent blog but have been too lazy to sign up for Blogger (or what have you).

Have you seen the Casco ( about $400) pencil sharpener made in Spain? Perhaps, that’s the one you’re holding in reserve.

Except that this is not an article about pencil sharpeners…

I did not know about the Mt. Blanc cap sharpener.

Do they make big lead holders or just for small?

Nice post btw.

Duc

Thank you! I recently purchased a Staedler 502, and I just couldn’t work out how to make it sharpen my leads. Your link to the .pdf file saved the day.

My own personal experience sharpening a 5.6mm lead with a standard medium quality blade sharpener was disastrous – the sharpener blunted on its first attempt at sharpening these behemoths. I think sharpening graphite only dulls the blade more than a normal pencil – just my experience.

This web site is the most informative of anywhere I have been on net. Thanks you very much.

Has anyone found that its very hard to find a Rotary Lead Pointer for 3 mm leads ? I was thinking about getting another STAEDTLER Rotary Lead Pointer and just drilling out the hole to 3 mm to see if it will work with my 3 mm leads.

Comments and recommendations please.

P.S. I commonly remove the wood from my standard “B” drawing pencils and they are 3 mm. I use them in my 3 mm lead holder.

Hi Marc, thank you for the praise.

The Gedess pointer will work with 3.15mm lead, though as mentioned, it is a different concept than the Staedtler 502.

Your wood removal technique is also interesting, as these leads can be quite expensive.

Gedess pointer. Great. I appreciate you taking the time to answer.

I have been doing a lot of research and wasn’t having any luck finding something to sharpen the 3 mm [3.15mm] leads I have. After reading your reply I found one [ttp://www.leadholder.com/point-gedess.html]. Still having a hard time finding a place where I can purchase it/order it.

Question on the Gedess pointer, do you think its better or comparable to the sharpness you get with the Rotary style pointers ? I guess it doesn’t matter as there doesn’t seem to be much of a choice for 3mm lead sharpeners.

Yes… I have had some funny looks when people see me removing ALL the wood from my “B” pencils. This strange process all started when I received my first vise-grip jaw lead holder. I recieved a lot of 2 mm “HB” leads and over a year… use them up. I loved using the lead holder so much that I just started taking regular pencils and removing the woods and using the leads. When I began to learn to shade and understand value… I just started removing the wood from all my pencils and using them in my lead holder.

I didn’t understand why the leads in my “B” pencils weren’t fitting in my lead holder and I set out researching on the net on a vise-grip jaw lead holder that would fit the 3/3.15mm leads I was getting out of my “B” pencils. I purchased my second vise-grip jaw lead holder, Alvin TECH DA Lead Holder – for 2mm to 3mm Leads, a few months ago and am forced to use sand paper and the hand held plastic sharpener, as I call them… to sharpen my 3 mm “B” leads.

As you can tell… I am self taught and take a non-traditional approach. I am sure the you and the majority of the readers here purchase 3.15 mm leads and do not use my wood removal methods. I wouldn’t even know where to get a 3.15 mm lead…:)

As I am researching I just now realize that I can purchase 2mm leads in the full range of “B” softnesses… lol. I am silly sometimes, but I do have fun.

Thanks again. Sorry for all the brain droppings. Hope this helps someone. I appreciate all your help.

Marc (and anyone else who cares),

I think your technique of removing the lead from wooden pencils is not entirely nuts, it’s only mostly nuts. I’ve collected a few anecdotes from old-timers who would resort to such measures in a pinch. I suspect the technique was fairly widespread in the early days of removable lead drawing pencils when the naked leads cost more than the pencils which had much longer leads in them. For no good reason I can think of, the price of naked leads has almost always been only slightly less than wooden pencils with the same lead in them.

The process of making leads is: Make leads*. Stamp name on them. Package them.

Whereas the process of making pencils is something like this:

Make leads*. Harvest cedar. Dry cedar. Cut cedar. Mill grooves in cedar. Glue leads in cedar. Mill cedar with leads embedded to shape of pencil. Apply color finish to pencils (probably in multiple coats). Varnish pencils. Foil stamp name in pencils. Package pencils.

* There are many, many steps to making the lead, but the process is the same whether they are sold naked or not.

Moving on… I’m wondering what technique you used to remove the wood from the lead?

There exists a trianglar shaped 3-hole handheld pointer that does this job, though it seems to be designed for pencils with only 2 mm leads. I must say it is strangely-fun to see if you can remove the wood entirely without breaking the lead.

The pointers used to be sold as Koh-I-Noor, though there was no name on them: http://www.leadholder.com/cat-kin-1985b-5.html (could the OEM be KUM?)

You can still buy them here: http://www.reuels.com/reuels/Alvin_Three_Hole_Sharpener.html

The description at Reuels is out of date. The 3-hole model has not had the lanyard loop since the early 1990s, I think, and the three holes work as follows: one hole sharpens a pencil in the usual way. One hole strips only the wood away. One hole is a not-very-good lead pointer.

Cheers.

You can purchase the Gedess lead pointer at http://www.pencilthings.com. I have been looking for a decent 3.15mm lead pointer ever since I picked up a Lamy Scribble. It appears though, to use the Gedess, the lead holder has to be a standard issue (i.e., the Lamy will not fit into the turret on top), so I am getting an Alvin Tech DA to use for sharpening the lead. It’s an extra step though, but if it provides a better point than the KUM 23 Automatic, it would be worth it. Never tried the 23 yet, getting it with the order of the Gedess, so I can compare. I’ve heard the blades don’t last very long in the KUM sharpeners…

You can use a mill bastard metal file to sharpen graphite lead. It works great and it’s better in my opinion than sandpaper. Also, a lot cheaper too.

Okay, so I love the feel of 5.6mm Koh-I-Noors and the Franklin-Christoph lead holders, and I use them in normal use for note-writing, but the point you normally get on a 5.6mm lead is meant for sketching & is not great for regular writing. So…I point the 5.6 lead body in a regular manual (repeat, manual) pencil sharpener. Given that a normal round pencil (yellow standard school) is around 7.3mm diameter and less than that for hex (6.8-7.0mm), the difference is not that great, and the 5.6mm lead fits fine into the sharpener. After twisting carefully, you get the 23deg point of a regular pencil, only now it’s all lead. To keep the narrower 5.6mm lead aligned and help keep it all vertical when sharpening, I’ve epoxied a small washer with a .250in/6.35mm diameter inner hole (standard size) on top of the cover of one of my two-hole manual Staedtler sharpeners as a guide. Kind of blocks part of the big hole, but I don’t use that one, and I could shave off the edge of the washer if really I needed to. In an case, the 5.6mm pencil has become, for me, a very practical and noticeably cool pencil for daily use, esp. in HB lead. Okay, I know you have to be a little strange to love this stuff, but to that I plead guilty! Thanks for everyone contributing to this forum! OBTW, for Marc, re removing leads? I do it regularly. I really like red and blue Col-Erase color leads (for the erasability, of course) so I cut them out of the wooden Col-Erase pencils and use them in my 3mm Caran D’Ache fixpencils. Works perfect & points great in one of those little red dual-hole 2mm/3.15mm KUM pointers, and it’s not too hard to do with an Exacto knife. I do the same and cut the leads out of regular yellow school pencils (not all the leads are alike, and I have a #2 brand that I prefer), which then fit perfectly into my 2mm fixpencils. The 5.6mm is my current fave, however!

I’m surprised that no one mentions FUGLE, the Cadillac of lead pointers back in the day (fifties and sixties). They were small round cylinders with four steel blades inside, hole in the top, through with you twirled the extended lead from your lead holder. The result was a point so sharp it was dangerous. A rubber vacuum cup was mounted on the bottom to secure it to a drafting board or table, anywhere a slick non-porous surface was available, like glass or plastic, but not wood.

Would like to buy one today, but don’t know where, so now I am busy sorting through my junk, looking for the two I had thirty or forty years ago.

John

HI THERE

I HAVE A TABLE MOUNTED STANDARDGRAPH 6501 LEAD POINTER/SHARPENER – DOES ANYBODY KNOW ANYTHING ABOUT THIS ITEM PLEASE ?

I use hard leads and have dulled most of the pointers I bought on amazon. The only one I have that continues to deliver is the old school Mars hand rotary pointer.

The others I’ve sharpener on a tiny whet stone (or with a carbide tiny flat screw driver in a pinch) but I always go back to the mars one.